Driving Efficiency: New Trends in Engine and Engine Component Design

The quest for more efficient, powerful, and environmentally friendly engines has led to significant advancements in engine and engine component design. These innovations aim to improve fuel economy, reduce emissions, and enhance overall performance. Here’s a comprehensive look at the latest trends shaping the future of engine technology.

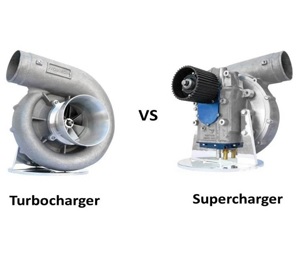

1. Turbocharging and Supercharging

Turbocharging and supercharging are technologies that increase an engine's power output without significantly increasing its size.

- Turbocharging uses exhaust gases to drive a turbine, which in turn compresses the air entering the engine. This allows more air (and fuel) to be burned, boosting power. Modern turbochargers are more efficient, reducing lag and improving responsiveness.

- Supercharging, on the other hand, uses a belt-driven compressor to achieve similar results. While it provides instant power, it tends to be less efficient than turbocharging. However, advances in electric superchargers are addressing these efficiency concerns, making them a viable option for performance enhancement.

2. Variable Valve Timing and Lift

Variable valve timing and lift technologies optimize the timing and duration of valve openings, improving efficiency and performance across different engine speeds.

- Variable Valve Timing (VVT) adjusts the timing of the valve openings, ensuring optimal air-fuel mixture and combustion at various engine speeds.

- Variable Valve Lift (VVL) changes the amount the valve opens, allowing for better control of the engine's breathing. This results in improved fuel efficiency and power output, especially in high-performance applications.

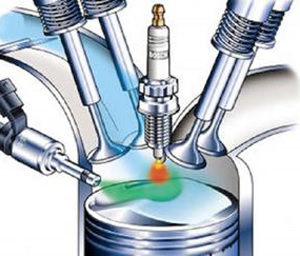

3. Direct Injection Systems

Direct injection systems deliver fuel directly into the combustion chamber, allowing for more precise control of the air-fuel mixture.

- Gasoline Direct Injection (GDI) systems provide better fuel atomization and combustion, improving efficiency and reducing emissions. This technology is becoming increasingly common in modern gasoline engines.

- Diesel Direct Injection (DDI) systems have been around for longer and continue to evolve, offering high efficiency and power output while meeting stringent emissions standards.

4. Lightweight Materials

Reducing the weight of engine components is crucial for improving efficiency and performance. Lightweight materials, such as aluminum, magnesium, and composites, are increasingly being used in engine design.

- Aluminum alloys are commonly used for engine blocks and cylinder heads due to their excellent strength-to-weight ratio and thermal conductivity.

- Magnesium alloys offer even greater weight savings and are used in components such as engine covers and brackets.

- Carbon fiber composites are also being explored for their exceptional strength and lightweight properties, though their high cost currently limits their widespread use.

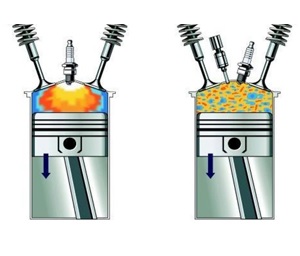

5. Advanced Combustion Technologies

Innovations in combustion technology are key to improving engine efficiency and reducing emissions.

- Homogeneous Charge Compression Ignition (HCCI) is a technology that combines the best features of gasoline and diesel engines. It uses a homogeneous air-fuel mixture like a gasoline engine but ignites it through compression like a diesel engine, resulting in high efficiency and low emissions.

- Controlled Auto-Ignition (CAI) is similar to HCCI but offers better control over the combustion process, making it more practical for real-world applications.

6. Electrification and Hybridization

The integration of electric power with traditional internal combustion engines is a major trend aimed at enhancing efficiency and reducing emissions.

- Mild Hybrids use a small electric motor to assist the engine during acceleration and to recover energy during braking, improving fuel economy without the complexity of a full hybrid system.

- Plug-in Hybrids (PHEVs) combine an internal combustion engine with a larger electric motor and battery pack, allowing for significant electric-only driving range and improved overall efficiency.

- Electric Turbocharging uses an electric motor to drive the turbocharger, eliminating lag and providing instant boost, while also allowing for more efficient engine operation.

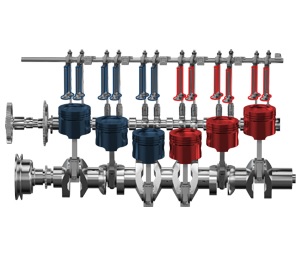

7. Cylinder Deactivation

Cylinder deactivation technology allows an engine to shut down some of its cylinders under light-load conditions, reducing fuel consumption.

- Modern systems can deactivate half or more of an engine’s cylinders, seamlessly transitioning between full and partial operation without the driver noticing. This technology is particularly effective in larger engines, such as V8s, where the fuel savings can be substantial.

8. Engine Downsizing

Engine downsizing involves using smaller engines with turbocharging and other technologies to deliver the power of larger engines with improved fuel efficiency.

- Small-displacement turbocharged engines are becoming the norm, especially in compact and mid-size vehicles. These engines provide excellent fuel economy during normal driving and strong performance when needed.

9. Exhaust Gas Recirculation (EGR)

EGR systems reduce nitrogen oxide (NOx) emissions by recirculating a portion of an engine’s exhaust gas back to the engine cylinders.

- Low-Pressure EGR systems cool the exhaust gases before recirculation, improving the effectiveness of NOx reduction and allowing for more aggressive engine tuning for performance and efficiency.

10. Stop-Start Systems

Stop-start systems automatically shut off the engine when the vehicle is stationary and restart it when the driver is ready to move again.

- This technology is particularly effective in reducing fuel consumption and emissions in urban driving conditions, where frequent stops are common.

Conclusion

The future of engine design is bright, with numerous innovations driving efficiency, performance, and environmental friendliness. From advanced turbocharging and direct injection systems to lightweight materials and hybridization, these trends are shaping the next generation of internal combustion engines. As these technologies continue to evolve, we can expect even greater improvements in fuel economy, emissions, and overall driving experience.