From Rack to Pinion: Innovations in Automotive Steering Components

Introduction:

The automotive industry is an ever-evolving field, driven by the constant pursuit of efficiency, safety, and innovation. One of the critical systems in any vehicle is its steering mechanism, which has undergone significant advancements over the years. From the early days of simple mechanical systems to the current state-of-the-art electronic steering, the journey of automotive steering components, particularly the transition from rack and pinion to modern innovations, highlights the technological progress and engineering ingenuity that defines the industry.

The Evolution of Automotive Steering

Steering systems have come a long way since the inception of the automobile. Initially, vehicles used rudimentary methods like tiller steering, which was soon replaced by the more familiar steering wheel and column. The introduction of the rack and pinion system marked a significant milestone in steering technology.

This mechanism, consisting of a circular gear (the pinion) engaging with a linear gear (the rack), allowed for more precise and responsive control, becoming the standard for many years.

Rack and Pinion Steering

Rack and pinion steering is renowned for its simplicity, reliability, and direct feedback. It offers several advantages:

- Precision and Control: The direct connection between the steering wheel and the wheels ensures accurate response to driver inputs.

- Compact Design: The system's straightforward design fits well in various vehicle architectures, making it versatile.

- Low Maintenance: With fewer moving parts compared to older steering systems, rack and pinion setups generally require less maintenance.

However, as vehicles became more sophisticated, the need for enhanced performance and safety features spurred further innovations in steering technology.

Power Steering: Enhancing Driver Comfort

The advent of power steering systems addressed the physical effort required to turn the steering wheel, especially in heavier vehicles. Hydraulic power steering (HPS) was the first significant development, using hydraulic pressure to assist in steering effort. While HPS made driving more comfortable, it had drawbacks such as energy inefficiency and a bulky design.

Electric Power Steering (EPS)

Electric Power Steering (EPS) emerged as a more efficient and adaptable solution. EPS systems use electric motors to provide steering assistance, offering several benefits:

- Energy Efficiency: Unlike HPS, which constantly draws power from the engine, EPS only uses energy when steering assistance is needed.

- Adaptive Steering: EPS systems can adjust the level of assistance based on driving conditions, improving both low-speed maneuverability and high-speed stability.

- Integration with Advanced Driver Assistance Systems (ADAS): EPS can easily integrate with ADAS technologies, enabling features like lane-keeping assist, automated parking, and collision avoidance.

Steer-by-Wire: The Future of Steering

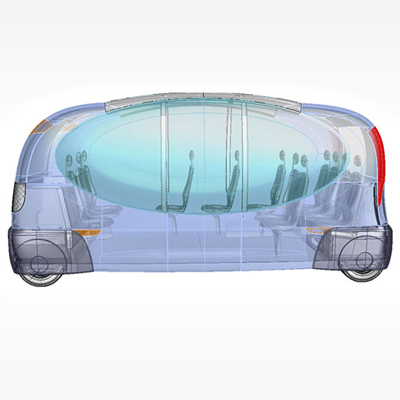

The next frontier in steering technology is steer-by-wire systems, which eliminate the mechanical connection between the steering wheel and the wheels. Instead, electronic signals control the steering actuators. This innovation offers several groundbreaking advantages:

- Flexibility in Design: Without the need for a physical steering column, vehicle interiors can be redesigned for improved ergonomics and safety.

- Enhanced Safety: Steer-by-wire can improve safety by reducing the risk of injury in a collision, as there is no steering column to cause harm.

- Customization: Steering response and feel can be tailored to individual driver preferences and driving conditions, providing a highly customizable driving experience.

- Integration with Autonomous Vehicles: Steer-by-wire is a critical component for the future of autonomous vehicles, allowing seamless integration with autonomous driving systems.

Innovations in Materials and Manufacturing

Advancements in materials and manufacturing techniques also play a crucial role in the evolution of steering components. Lightweight materials such as aluminum and composites reduce the overall weight of steering systems, contributing to better fuel efficiency and vehicle performance. Additionally, precision manufacturing techniques, including CNC machining and 3D printing, allow for the production of highly accurate and reliable steering components.

Conclusion:

The journey from rack and pinion to modern steering innovations underscores the dynamic nature of the automotive industry. Each advancement, from hydraulic and electric power steering to the revolutionary steer-by-wire systems, reflects the industry's commitment to enhancing driver experience, safety, and vehicle performance. As we move towards a future dominated by electric and autonomous vehicles, the continuous evolution of steering technology will remain at the forefront, steering the automotive world into new realms of possibility.