Automotive Industry 4.0: Revolutionizing Manufacturing with Digital Innovation and Smart Factories

Introduction:

The automotive industry has always been at the forefront of technological advancements, constantly evolving to meet the demands of a dynamic market. In recent years, a significant transformation known as Industry 4.0 has been sweeping through manufacturing sectors worldwide. This fourth industrial revolution leverages digital technologies to create smarter, more efficient, and interconnected production systems. In the automotive sector, this paradigm shift is manifesting as "Automotive Industry 4.0," where digital manufacturing and smart factories are reshaping the way vehicles are designed, produced, and maintained.

Understanding Industry 4.0:

Industry 4.0 denotes the incorporation of digital technologies into manufacturing processes, giving rise to what is commonly known as a "smart factory." This evolution is marked by the merging of the physical and digital realms, harnessing technologies like the Internet of Things (IoT), artificial intelligence (AI), big data analytics, robotics, and augmented reality. Within the automotive sector, Industry 4.0 instigates substantial transformations that amplify efficiency, adaptability, and sustainability across the entire production chain.

Digital Twin Technology:

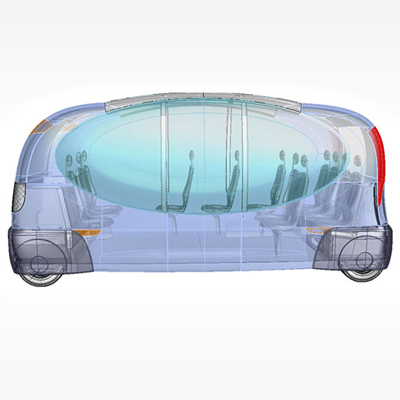

One of the key components of Automotive Industry 4.0 is the concept of a "digital twin." A digital twin is a virtual replica of a physical product or system, created through real-time data collection and analysis. In automotive manufacturing, digital twin technology allows companies to simulate and optimize every aspect of the production process. From designing components to testing prototypes, digital twins provide invaluable insights, reducing time and costs associated with traditional trial-and-error methods.

Connected Supply Chains:

Industry 4.0 fosters the development of connected supply chains, where different components of the manufacturing process are seamlessly integrated. This connectivity enables real-time communication between suppliers, manufacturers, and distributors. For the automotive industry, this means better coordination between various stakeholders, reducing delays and ensuring a more agile response to market demands. Connected supply chains also facilitate predictive maintenance, minimizing downtime by addressing potential issues before they lead to a breakdown.

Internet of Things (IoT) in Automotive Manufacturing:

In the realm of Automotive Industry 4.0, the Internet of Things assumes a crucial role by interconnecting physical devices and systems. Within the manufacturing landscape, IoT sensors are integrated into machinery and equipment, gathering data related to performance, efficiency, and maintenance requirements. For example, sensors on robots along the production line can track their health and alert maintenance teams when components require attention. This proactive maintenance strategy serves to preempt unforeseen breakdowns, thereby minimizing downtime and elevating overall operational efficiency.

Artificial Intelligence (AI) for Smarter Production:

Artificial intelligence stands as a catalyst for intelligent factories within the Automotive Industry 4.0. AI algorithms meticulously scrutinize extensive datasets produced by sensors and interconnected devices to fine-tune production processes. Machine learning algorithms exhibit the capability to anticipate equipment failures, enabling prompt maintenance, and can strategically optimize production schedules in response to real-time shifts in demand. This heightened level of intelligence contributes to more streamlined and adaptable manufacturing processes.

Robotics and Automation:

Robots have long been a staple in automotive manufacturing, but Industry 4.0 takes robotic automation to new heights. Advanced robotics, coupled with AI, enables greater flexibility and precision in manufacturing. Collaborative robots, or cobots, work alongside human operators, taking over repetitive and physically demanding tasks. This not only enhances efficiency but also improves worker safety. The automation of certain processes also allows for faster production cycles and the ability to quickly reconfigure production lines for different models.

Big Data Analytics for Informed Decision-Making:

Utilizing Big Data Analytics for Enlightened Decision-Making:

The substantial volumes of data emanating from connected devices in smart factories represent a valuable trove of information. Big data analytics meticulously sifts through this data to unveil patterns, trends, and areas warranting enhancement. Within the automotive industry, this entails scrutinizing data from production lines to pinpoint bottlenecks, refining inventory management, and even prognosticating market trends based on customer preferences. Informed decision-making, supported by data analytics, stands as a foundational element of Automotive Industry 4.0.

Augmented Reality (AR) for Enhanced Training and Maintenance:

Augmented reality is changing the way employees are trained and maintenance tasks are performed in automotive manufacturing. AR applications provide interactive, real-time guidance to workers, especially in complex assembly processes. For maintenance technicians, AR overlays digital information onto physical equipment, offering step-by-step instructions for repairs. This not only reduces the learning curve for new employees but also enhances the speed and accuracy of maintenance activities.

Challenges and Opportunities:

While the benefits of Automotive Industry 4.0 are vast, implementation does not come without challenges. Companies need to invest significantly in technology infrastructure, data security measures, and employee training to fully leverage the potential of digital manufacturing. Moreover, there are concerns about the potential displacement of jobs as automation becomes more prevalent. However, Industry 4.0 also presents opportunities for upskilling the workforce, creating new roles focused on managing and maintaining the advanced technologies driving smart factories.

Conclusion:

Automotive Industry 4.0 is revolutionizing the way vehicles are manufactured, bringing unprecedented levels of efficiency, flexibility, and connectivity to the production process. Digital manufacturing and smart factories powered by technologies such as IoT, AI, robotics, and big data analytics are transforming traditional assembly lines into adaptive and intelligent systems. As the automotive industry continues to embrace these innovations, it is poised for a future where agility, sustainability, and innovation define the manufacturing landscape. The journey to Automotive Industry 4.0 represents not just a technological shift but a fundamental transformation in how cars are conceived, built, and maintained.